The previous article dealt

with the manual scanning method of ultrasonic examination stating that

accurate determination of weld flaw size and position - to within ±2mm

- was difficult, if not impossible, in most circumstances. Methods

developed now enable flaw sizes to be determined with accuracy better

than ±1mm. This article will look at two of these techniques; time of

flight diffraction (TOFD) and phased array ultrasonic testing (PAUT).

Conventional manually scanned ultrasonic testing normally uses a single fixed angle and frequency probe; the position and size of a flaw being determined by the amplitude of the signal reflected from the flaw and presented on an oscilloscope screen (Fig 3 in Job Knowledge 128). This is a somewhat unreliable method as the amplitude of the signal and therefore an estimate of its size depends on the orientation of the flaw. TOFD uses two angled compression wave probes mounted on a frame so that they are a fixed distance apart; one a transmitter, the other a receiver. The probes are positioned either side of a weld as shown in Fig 1. In a flaw-free weld two sound waves will be detected by the receiver – one that travels along the surface of the weld, the lateral wave, and one reflected from the back wall. When a flaw is present (for example a crack as shown in Fig 1) the pulse emitted by the transmitter is diffracted or scattered from the tip of a flaw and this diffracted signal is picked up by the receiver. The time of flight of the signal is measured and compared with that of the lateral wave, a simple calculation enables the position of the tip of the flaw to be determined. Moving the probes in a predetermined scanning pattern enables the other end of the flaw to be detected so the flaw size can be established in both the trough thickness and longitudinal directions. The calculations are performed automatically by the software program within the equipment and the flaws displayed as a black and white A scan image.

Conventional manually scanned ultrasonic testing normally uses a single fixed angle and frequency probe; the position and size of a flaw being determined by the amplitude of the signal reflected from the flaw and presented on an oscilloscope screen (Fig 3 in Job Knowledge 128). This is a somewhat unreliable method as the amplitude of the signal and therefore an estimate of its size depends on the orientation of the flaw. TOFD uses two angled compression wave probes mounted on a frame so that they are a fixed distance apart; one a transmitter, the other a receiver. The probes are positioned either side of a weld as shown in Fig 1. In a flaw-free weld two sound waves will be detected by the receiver – one that travels along the surface of the weld, the lateral wave, and one reflected from the back wall. When a flaw is present (for example a crack as shown in Fig 1) the pulse emitted by the transmitter is diffracted or scattered from the tip of a flaw and this diffracted signal is picked up by the receiver. The time of flight of the signal is measured and compared with that of the lateral wave, a simple calculation enables the position of the tip of the flaw to be determined. Moving the probes in a predetermined scanning pattern enables the other end of the flaw to be detected so the flaw size can be established in both the trough thickness and longitudinal directions. The calculations are performed automatically by the software program within the equipment and the flaws displayed as a black and white A scan image.

Figure 1: TOFD

Various scanning patterns may be used so

that the results can be presented as A-scan, B-scan, looking along the

weld length or D-scan, a side view. (For a description of A, B, C and D

scans see Job Knowledge No. 127).

TOFD is regarded as the best method for the detection and sizing of planar, through-thickness flaws. One limitation is the detection of small surface breaking flaws on the scanning surface as these tend to be lost in the lateral wave response, although this may be not too significant as most surface breaking defects can be readily detected using MPI or liquid penetrant methods.

The rapid progress of electronics and computing power has enabled complex methods of scanning and data processing to be developed. This has culminated in phased array ultrasonic testing (PAUT) which, as the name suggests, uses an array of small transducers unlike the conventional manual A-scan probe with only one transducer. A single PAUT probe may contain between several tens and several hundreds of transducers. These small transducers are computer controlled and can be pulsed independently in a set sequence or phase; the pulses of sound interfering with each other to produce a sound beam of a certain angle, see Fig. 2. By varying the time and pattern of the pulses, the angle and shape of the beam can be varied so that the beam can be steered electronically, sectorial scanning or S-scan.

TOFD is regarded as the best method for the detection and sizing of planar, through-thickness flaws. One limitation is the detection of small surface breaking flaws on the scanning surface as these tend to be lost in the lateral wave response, although this may be not too significant as most surface breaking defects can be readily detected using MPI or liquid penetrant methods.

The rapid progress of electronics and computing power has enabled complex methods of scanning and data processing to be developed. This has culminated in phased array ultrasonic testing (PAUT) which, as the name suggests, uses an array of small transducers unlike the conventional manual A-scan probe with only one transducer. A single PAUT probe may contain between several tens and several hundreds of transducers. These small transducers are computer controlled and can be pulsed independently in a set sequence or phase; the pulses of sound interfering with each other to produce a sound beam of a certain angle, see Fig. 2. By varying the time and pattern of the pulses, the angle and shape of the beam can be varied so that the beam can be steered electronically, sectorial scanning or S-scan.

Figure

2: Illustration of the sector scan composed of many A-scans from the

beams being steered through a range of angles. Note that, in addition to

steering the beam, the focal law may also be focusing the sound field

to improve defect detection and resolution

The benefits of this technology compared

with conventional single transducer scanning are that the beam can be

steered and focused with a single probe. Beam steering enables the beam

to be swept through an object without moving the probe, the reflected

data being processed to provide a visual image of a cone shaped slice

through the object. Moving the probe enables a large number of slices to

be assembled to provide a three dimensional image – a good example is

the use in medical diagnostics to examine the functioning of the heart

in real time.

For the non-destructive examination of welds this ability to inspect a weld with multiple angle beams from a single probe means that the probability of detecting flaws is greatly increased. It is also possible to focus the beam electronically at multiple depths to improve the ability to accurately determine the size and position of weld flaws.

For the non-destructive examination of welds this ability to inspect a weld with multiple angle beams from a single probe means that the probability of detecting flaws is greatly increased. It is also possible to focus the beam electronically at multiple depths to improve the ability to accurately determine the size and position of weld flaws.

Figure 3: Phased array results showing A-scan, B-scan and S-scan of a nozzle to shell weld

The small probe size and the ability to

manipulate the beam without moving the probe enables inspections in

limited access or of components of a complex shape. Cost is also a

factor – although the probes and the processing/display units are more

expensive than the single transducer equipment, the time to perform a

scan can be substantially reduced. Work carried out by TWI suggests that

a phased array scan can take 20% of the time for a conventional scan

with better coverage although the off-line interpretation of the results

may take longer.

The results may be presented as S-, A-, B- or C-scans, enabling better interpretation. The results of a phased array examination of a single sided nozzle to shell weld is given in Fig. 3. The weld shape is given by the red lines superimposed on the S-scan display. This is a single sided weld, the lower half of the image being a mirror of the weld. Whilst the scanning operation may be performed automatically by mechanised manipulating equipment and the accuracy may be better than ±1mm, the interpretation must be carried out by experienced and skilled personnel trained specifically in the interpretation of phased array scanning results. An investigation by TWI showed that the skill of the individual carrying out the interpretation was by far the most important factor in producing reproducible and accurate results.

Scanning can be performed manually or with the probe attached to a carriage. A typical application is the examination of pipe butt welds using orbiting crawler tractors

Such dedicated and robust mechanised equipment is readily available for site use, replacing radiography and giving benefits in terms of cost, flaw detection and health and safety issues.

An excellent example of the capabilities of PAUT is given in the article ‘Measuring the crack growth rate (da/dt) of a fatigue crack using phased array ultrasonics’ by Channa Nageswaran, Principal Project Leader at TWI.

This article was written by Gene Mathers.

The results may be presented as S-, A-, B- or C-scans, enabling better interpretation. The results of a phased array examination of a single sided nozzle to shell weld is given in Fig. 3. The weld shape is given by the red lines superimposed on the S-scan display. This is a single sided weld, the lower half of the image being a mirror of the weld. Whilst the scanning operation may be performed automatically by mechanised manipulating equipment and the accuracy may be better than ±1mm, the interpretation must be carried out by experienced and skilled personnel trained specifically in the interpretation of phased array scanning results. An investigation by TWI showed that the skill of the individual carrying out the interpretation was by far the most important factor in producing reproducible and accurate results.

Scanning can be performed manually or with the probe attached to a carriage. A typical application is the examination of pipe butt welds using orbiting crawler tractors

Such dedicated and robust mechanised equipment is readily available for site use, replacing radiography and giving benefits in terms of cost, flaw detection and health and safety issues.

An excellent example of the capabilities of PAUT is given in the article ‘Measuring the crack growth rate (da/dt) of a fatigue crack using phased array ultrasonics’ by Channa Nageswaran, Principal Project Leader at TWI.

This article was written by Gene Mathers.

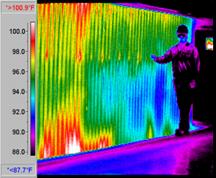

Fig 1: Pressure Pipe Testing Installation for Infrared Thermography Test.

Fig 1: Pressure Pipe Testing Installation for Infrared Thermography Test.